Notable market developments

- Orora's new glass beneficiation facility in Kingsford, South Australia (SA) commenced operations in October. Orora’s new facility will process 100,000–150,000 tonnes per year, helping it reach its target of 60% recycled content in its glass packaging manufacturing by 2025. The facility will mainly target container deposit scheme (CDS) glass from SA, Western Australia (WA) and potentially Victoria once the CDS is in operation.

- Fulton Hogan Industries is developing a new glass crushing plant in Lara, Victoria. Fulton Hogan has received $740,000 in state and Australian Government funding to develop a regional glass processing hub to make feedstock for asphalt. The facility will have the capacity to process 10,000 tonnes per year of regionally generated glass packaging.

- Repurpose-It in Epping, Victoria is expanding its glass washing capacity by 50,000 tonnes per year. Repurpose-It has received $400,000 in state and Australian Government funding which will go towards the installation of an additional centrifuge and material storage bunker for crushed packaging glass processing and allow the diversion of the glass into a wider range of construction applications.

- Visy undertakes glass packaging beneficiation and glass packaging manufacture. Visy has expanded its Laverton, Victoria based beneficiation facility by an additional 100,000 tonnes per year. Visy is also expecting to make a substantial investment in upgrading and increasing the capacity of glass packaging furnaces, including at its Spotswood facility in Melbourne. Visy media statements indicate a target to produce bottles from 60–70% recycled content (up from 30–35% in 2020). Visy is currently reporting they have achieved 43%. An increase of 35% (since 2020) in recycled content will grow local demand for recycled glass by around 300,000 tonnes per year.

- Increased beneficiation interstate. ReGroup (formerly Polytrade) is commissioning a new glass beneficiation plant in Sydney. This facility will reprocess glass packaging from New South Wales that was previously going to Melbourne. This may relieve some of the constraints on beneficiation capacity in Victoria.

Material overview and market summary

Visy and ReGroup’s glass beneficiation plants are the only two Victorian plants taking glass packaging from kerbside collections and making this material furnace-ready to make new glass bottles. The current combined annual throughput of these plants is just over 100,000 tonnes.

This is insufficient to handle the total volume of glass collected in kerbside recycling bins in Victoria, which is approximately 170,000 tonnes into material recovery facilities (MRFs). It is also important to note that around 280,000 tonnes per year of end-of-life glass packaging is generated, mostly from households, but some from commercial sources.

Most of the collected glass that is beyond the current beneficiation capacity is going into road base and a range of other applications through companies such as Alex Fraser and Repurpose-It. This glass is washed and crushed and goes into a wide range of built environment applications.

Nationally it is particularly the more contaminated glass collected through MRFs that continues to be destined for road construction or landfill remediation, as CDS generated glass is preferred for new packaging manufacture. The demand for packaging glass-based sand replacement product is high in Victoria as it competes well on price and quality with quarried sand. In recent months this demand has increased, and the commercial value of the recycled glass has improved.

Visy announced in April 2022 the investment of $35 million into an expansion of its glass beneficiation operations at Laverton and upgrades of glass packaging manufacture at Spotswood. These upgrades are underway. This expansion of the Laverton based beneficiation facility will add another 100,000 tonnes per year of Victorian beneficiation capacity.

Visy is also expecting to make a substantial investment into upgrading and increasing the capacity of glass packaging furnaces nationally, including at Spotswood in Melbourne. Media statements by Visy indicates a target to produce bottles from 60–70% recycled content (up from 30–35% in 2020). At present Visy are reporting it has achieved 43%. An increase in recycled content of 30–35% will increase local demand for recycled glass by around 300,000 tonnes per year.

Polytrade has been sold to ReGroup, who are commissioning a new glass beneficiation plant in Sydney. This facility will reprocess glass packaging from NSW that was previously coming to Melbourne. This may relieve some of the constraints on beneficiation capacity in Victoria.

In addition, Orora commissioned a 100,000–150,000 tonnes per year glass beneficiation facility in Kingsford SA, which will support Orora in its target to achieve a 60% recycled content in the glass packaging it manufactures in SA by 2025. The facility will mainly target CDS glass in SA and WA, but it is also possible (even likely) that CDS glass from Victoria will also be eventually transported interstate to this facility for beneficiation.

The ability of Visy, ReGroup and Orora to increase their beneficiation capacity for returning most of the glass back into packaging is a further boost to glass recycling markets. The expansion of the Visy capacity is timed to coincide with the move to separate glass collection and the Victorian Government’s 2023 introduction of CDS in Victoria. The new ReGroup and Orora capacity, while interstate, is available now.

The growing market demand for recycled glass reported by industry sources may flow through to higher value commercial rates for sorted glass.

There are higher prices being offered for sorted beneficiated glass into the export market, with the export of unbeneficiated glass banned in 2020. There is no significant export occurring yet, and shipping costs may curtail this in the near future. However, this market may grow in the longer term, which may impact the market for crush glass into sand and aggregate products.

In July and August 2022 there were small quantities of beneficiated glass exported from Queensland (but none from Victoria) at a Customs reported value of $470 per tonne and $620 per tonne respectively. Interestingly, these prices are similar to the estimated price range for the value of virgin materials into new glass packaging of $600–$700 per tonne. However, the quantities of this glass, at only 65 tonnes in total, make it premature to draw any conclusions about the future viability and scale of export markets for Australian beneficiated glass.

Overall, the market for sorted glass packaging is much stronger than it has been in recent years. A challenge will be to maximise circularity such as recycling back into bottles and jars as opposed to road base.

The glass packaging collected through separate glass kerbside collections can be of a good quality for recycling back into bottles. The CDS sourced glass will also be of a much higher quality than the material coming through commingled collection systems as sorted by MRFs.

Visy and Orora have committed to lifting the recycled content of their glass packaging from ~35% in 2020 to 60–70% by 2025, in line with the growing beverage producer preference for higher recycled content. An increase in recycled content of 35% will increase local demand for recycled glass by around 300,000 tonnes per year.

As reported widely, the Victorian Government announced the statewide introduction of a separate glass recycling service from 2021. State government support for local government introduction has been announced. A number of councils are consulting with their communities on recycling system changes, including a glass recycling bin. A summary of the information on new glass bin service configurations is provided in the following table. This table will be updated as more services commence across the state.

Table 1: Glass bin (separate) service configurations.

| Council | Frequency | Bin size (L) | |

|---|---|---|---|

Council Hobsons Bay | Frequency Monthly | Bin size (L) 120 | |

Council Macedon | Frequency Monthly | Bin size (L) 140 | |

Council Moyne | Frequency Monthly | Bin size (L) 120 | |

Council Surf Coast | Frequency Monthly | Bin size (L) 140 | |

Council Warrnambool | Frequency Fortnightly | Bin size (L) 120 | |

Council Yarra | Frequency Fortnightly | Bin size (L) 80 |

Source: Recycling Victoria.

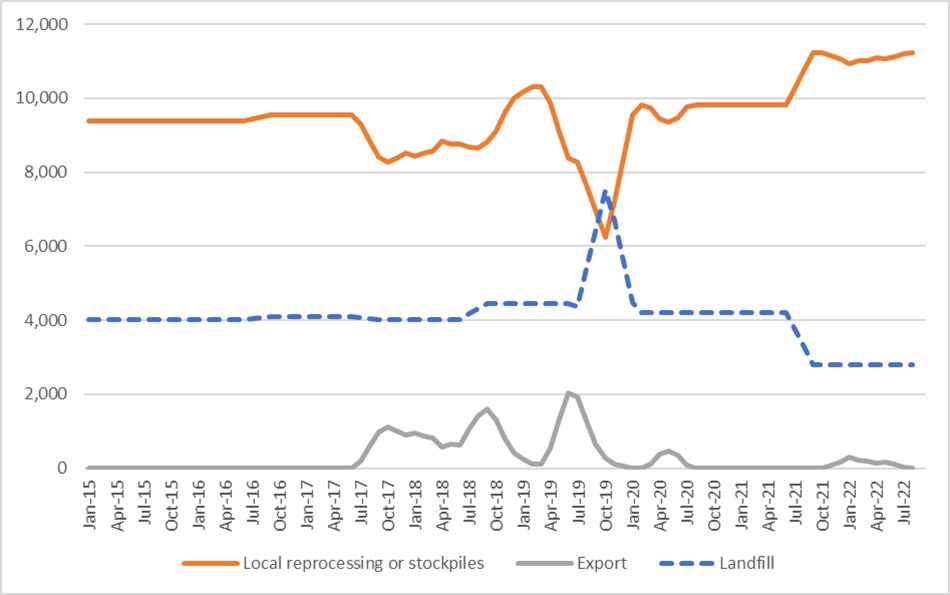

Figure 1 provides data on movements in export and local destinations of kerbside collected glass since the beginning of 2015. Exports of kerbside glass are generally low and sporadic, with minimal exports occurring since July 2020.

Prices, demand and supply

Gate fee rates for MRFs sending material for beneficiation can vary, based on quality and quantities. Gate fees of $0 per tonne at the outgoing gate of the MRF (EXW MRF) to -$30 per tonne are reported if the glass is going to beneficiation. Prices are lower if the glass is going into other applications (such as road construction), as the competing gate fee is straight to landfill.

The cost of beneficiation for food grade packaging is estimated at around $150–$200 per tonne but is dependent on the source and processing requirement of the incoming glass. The value of glass exports, which are required to be beneficiated, were reported to Customs at values of $470 per tonne and $620 per tonne respectively for July and August 2022 (from Queensland only), which is a significant increase on earlier reported values of around $120 per tonne. However, the quantities exported are relatively very small, in the context of overall glass beneficiation throughput.

Following beneficiation, Visy Glass receives the glass cullet from beneficiation plants in most major cities nationally, including Melbourne at its Spotswood facility. The price paid at these facilities has remained largely unchanged in recent years. Orora is now beneficiating glass at its new facility in Kingsford SA, for use in its only glass packaging manufacturing facility, which is also in SA.

The limited beneficiation capacity has restricted the amount of glass suitable for production. There is an increased focus on addressing this shortfall in beneficiation capacity, both in Victoria and in other states.

Delivered MRF sorted mixed glass destined for road base or asphalt production incurs a gate fee that is greater than the fee into beneficiation, but less than a landfill gate fee. On average it is expected to be around -$50 to -$80 per tonne (cost to the MRF operators).

Victoria regularly receives substantial kerbside glass imports from New Zealand, along with much smaller quantities from other countries. In August, 1,000 tonnes were imported from New Zealand to Australia. Most went to NSW, with only 60 tonnes going to Victoria. It is reported that this is mostly, or perhaps entirely, transfers from Visy Recycling New Zealand to Visy Recycling Australia.

Key end markets and related specifications

While the market for used glass packaging back into packaging production may fall short of national demand there are a range of other secondary markets that can be used. These include the major market of glass into asphalt, road-base material and sand for construction, and smaller markets for abrasives, and filter media.

Export and interstate market review

Glass cullet is not exported in significant volumes due to its low value and significant weight relative to shipping costs. However, this market may develop if large quantities of high-quality beneficiated glass grow in availability. Previous exports of glass cullet from Victoria have been almost entirely to Malaysia or Bangladesh, with Malaysia the only destination over the last 12 months. From January 2021 all exports of glass packaging have required a license, with unprocessed (unbeneficiated) glass not eligible for export.

Market opportunities

There is more glass in supply than there is beneficiation capacity. This is being addressed in part through the announced Visy, ReGroup and Orora beneficiation facilities, both in Victoria and interstate. This may result in less interstate glass coming to Victoria which will free up Victorian capacity.

The national glass demand (back into packaging) may not be able to absorb all the packaging glass supply, even if beneficiated. As a result, significant non-packaging end markets for recovered glass may continue to be required, or export markets for the beneficiated glass could be an environmentally positive solution.

Other end markets for the glass, such as the construction sector, may be needed even though this is a less circular solution.

Report disclaimer

The information on this report was prepared in conjunction with Blue Environment, IndustryEdge and Sustainable Resource Use (SRU).

While reasonable efforts have been made to ensure that the contents of this publication are factually correct, Recycling Victoria gives no warranty regarding its accuracy, completeness, currency or suitability for any particular purpose and to the extent permitted by law, does not accept any liability for loss or damages incurred as a result of placed upon the content of this publication.

This publication is provided on the basis that all persons accessing it undertake responsibility for assessing the relevance and accuracy of its content.

Recycling Victoria does not accept any liability for loss or damage arising from your use of or reliance on the data. The inclusion of information in this report does not constitute Recycling Victoria’s endorsement of any particular facility, or any associated organisation, product or service.

Accessibility disclaimer

The Victorian Government is committed to providing a website that is accessible to the widest possible audience, regardless of technology or ability.

This page contains an embedded complex image file (Figure 1) that may not meet our minimum WCAG AA Accessibility standards.

If you are unable to read any of the content of this page, you can contact the content owners for an Accessible version.

Contact email: rvdata@delwp.vic.gov.au

Updated